Categories

Tags

-

#ultra fine mist sprayer

#fine mist sprayer pump

#Cosmetic sprayer

#lotion pump head

#Perfume Spray Head

#sprayer

#Treatment Pump Manufacturers

#Perfume Spray Pen Head

#powder suction pump Manufacturers

#Fine Mist Sprayer Pump Head

#Cosmetic Sprayer Foam Pump Suppliers

#wholesale Cosmetic wholesale Treatment Pump

#pocket perfume pen supplier

#treatment pump manufacturer

Archives

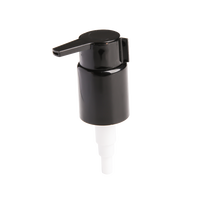

The Overall Function Of Lotion Pump Head

-

The lotion pump head is one of the most popular dispensing methods for viscous (thick liquid) products in the personal care and beauty industries, and it comes in various shapes and sizes. Many of these parts are plastic injection molded! When used as designed, the pump dispenses the correct amount of product again and again. But, have you ever thought about what is in the lotion pump head to make it work? Although there are hundreds of different designs on the market today, the basic principles are the same. Here is an overview of these components and how they contribute to the overall function of pulling the product from the bottle into your hands.

Generally speaking, a lotion pump head consists of the following components:

Actuator: The actuator or pump head is a tool that the consumer presses to pull the product out of the container. The actuator is usually made of polypropylene plastic and can have many different designs-and often has a lock or lock function to prevent accidental output. This is one of the component designs. The appearance design can separate one pump from another. This is also the part where ergonomics plays a role in improving consumer satisfaction.

Closure: The assembly that screws the entire assembly to the neck of the bottle. It is identified by common neck dressing destinations, such as 28-410, 33-400. It is usually made of polypropylene plastic and is usually designed with rib or smooth sides. In some cases, a shiny metal casing can be installed to give the lotion pump a high-end, elegant appearance.

External gasket: The gasket is usually fixed to the inside of the bottle cap by friction fit, and acts as a barrier to the gasket on the joint area of the bottle to prevent product leakage. According to the manufacturer's design, this outer gasket can be made of many materials: rubber and LDPE are just two of the many possible options.

Housing: Sometimes referred to as the housing of the pump assembly, this assembly holds all the pump components in place and acts as a transfer chamber, sending the product from the dip tube to the actuator, and ultimately to the user's hand. This part is usually made of polypropylene plastic. Depending on the output and design of the lotion pump, the size of the housing may vary greatly.

Stem/piston/spring/ball (internal parts inside the housing): These are parts that vary according to the design of the lotion pump. Some may even have additional components to assist product flow, and some designs may even have additional housing components that isolate the metal spring from the product channel. These pumps are often referred to as having a "metal-free channel" function, in this case, The product will not come into contact with the metal spring-eliminating the potential compatibility problem of the metal spring.

Immersion tube: A long plastic tube made of polypropylene plastic that extends the range of action of the emulsion pump to the bottom of the bottle. Depending on the bottle paired with the pump, the length of the dip tube will vary. A correctly cut dip tube will maximize product use and prevent clogging.