What Are The Advantage Of Stack Plastic Pail Mould

-

1, What is Stack Plastic Pail Mould

Stack mould is a cutting-edge technology in the development of plastic molds today. The cavities are distributed on two or more levels and arranged in an overlapping manner. Simply put, stack mould is equivalent to stacking multiple single-layer molds together and installing them on an injection molding machine for injection production.

stack mould usually use single-layer plastic injection molds for injection molding machines, and their injection volume and mold opening stroke only use 20% to 40% of the rated, which does not give full play to the performance of the injection machine, and laminated injection molds On the basis of not increasing the clamping force, the output can be doubled according to the number of layers under the condition of one injection machine and one operator, which can greatly improve production efficiency and equipment utilization, and can save production costs. stack injection molds are most suitable for molding large flat parts, shallow cavity shell parts, small multi-cavity thin-walled parts, and parts that require mass production.

2, What are the advantages of stack mould

A. Compared with the conventional mold, the clamping force of the laminated mold is only increased by 10%-15%, but the output can be increased by 90%-95%;

B. The mold manufacturing requirements are basically the same as those of conventional molds, and multiple cavities are combined in one mold, so the mold manufacturing cycle is greatly shortened;

C. The use of high-efficiency laminated injection molds can double or quadruple the output of ordinary single-layer molds without the need to invest in additional machinery and equipment. This saves the cost of installing machinery, equipment, expanding factory buildings and adding labor;

D. Stacked molds can be installed on injection molding machines with similar requirements for single-layer molds, but the output efficiency per unit time is doubled;

E. Save raw materials, easy to automate, improve product performance, and shorten production cycle;

3, Classification of stack mould

A. Ordinary stacked mould

- 2-layer mold

- 3-layer mold

- 4-layer mold

- Up to 10 layers

B. Rotating stacked mould

- Double-layer double-sided rotation 180 degrees each time

- Double layer 4 sides rotate 90 degrees every time

- 3 layers, 2 sides (180 degrees rotation each time) + 4 sides (90 degrees rotation each time)

C. Tandem mould

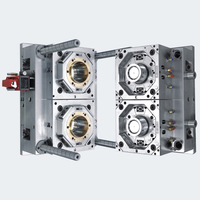

4, Stack mould structure

Two layer stack mould basic components

Stacked hot runner design

a, The movement orientation of the main nozzle

b, Connection of main nozzle and runner plate

c, Connection between runner plate and hot nozzle

d, Integrated design of wire frame, junction box and hot runner

e, Balancing technology of hot runner

f, Consideration of the convenience of assembly and disassembly of the hot runner

g, Protection of hot runner system

5, Points to consider in stack mould design

a, After the mold is opened, the main filling nozzle can not come out of the guide sleeve. Pay attention to the reasonable setting of the length of the main filling nozzle and the mold opening stroke;

b, The maximum mold opening stroke and maximum plasticization amount of the injection molding machine need to be checked;

c, The pre-plasticizing efficiency of the injection device should be high;

d, Increase the injection rate appropriately;

e, Pressure release of the hot runner melt;

f, Deal with the relationship between cavity layout and main irrigation nozzle.

We are a professional molding company, sell different design of mold, 20L Pail Mould is one of them,welcome to visit our website.