Forums » Off-Topic Discussions

WHAT IS A BORESCOPE?

-

WHAT IS A BORESCOPE?

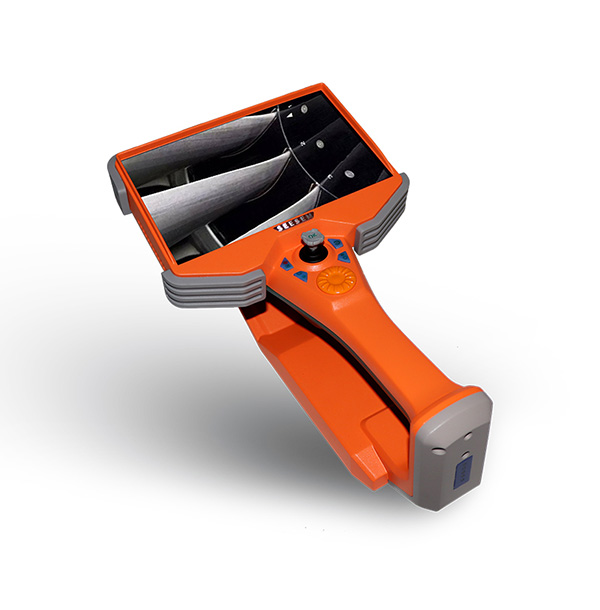

Industrial borescopes allow for remote visual inspections (RVI) in areas where it is difficult or impossible for the human eye to see into directly. However, the term “borescope” has become a generic term to describe four types of products/technologies used for internal inspections. While there are key differences between these inspection cameras, the earliest RVI product was called a “borescope” – the name stuck even as new technologies were developed.To get more news about video borescope, you can visit seesemborescopes.com official website.

Borescopes serve a multitude of applications including aviation, aerospace, sanitation, automotive, weaponry, metal casting, law enforcement, electronics, refining, and power generation. In order to accommodate a variety of industries, borescopes vary in length, diameter, and functionality. To answer the question “What is a Borescope?”, let’s take an in-depth look at each type of borescope.

.Rigid borescopes, still used for gun barrel or borehole inspections today, are ideal for applications that require only straight-line access to an inspection target. Rigid borescopes are simple tubes shaped like long, thin telescopes that use a lens system to send an image to a relay lens from the object to be viewed in real-time. This is accomplished with an eyepiece on the proximal (near) end and an angled mirror pointed toward an opening in the tube on the distal (far) end.

While rigid scopes have excellent image quality, they are limited to only accessing internal parts that can be viewed in a direct, straight line. In addition to gun barrels, they are often the best option for very small bore, straight pipe, or small part inspection, but do not work well for viewing inside objects with irregular internal cavities.

SEMI-RIGID SCOPES

A step up from rigid borescopes, semi-rigid borescopes are bendable and best for confined spaces that do not offer room for articulation. Semi-Rigid borescopes are more forgiving and durable than the rigid borescope, which is mainly due to technological progressions and their ability to bend. However, they are known for having a poorer image quality than other types of borescopes, which may deter companies requiring high-resolution image viewing.Some of these semi-rigid scopes are also classified as fiberscopes, which are offered in semi-rigid and articulating forms. The image will suffer from pixelation; the viewing screen and photos will display tiny black dots caused by the broken pixels. Once the strands start to break down, there is no repairing them and the entire unit will have to be replaced.