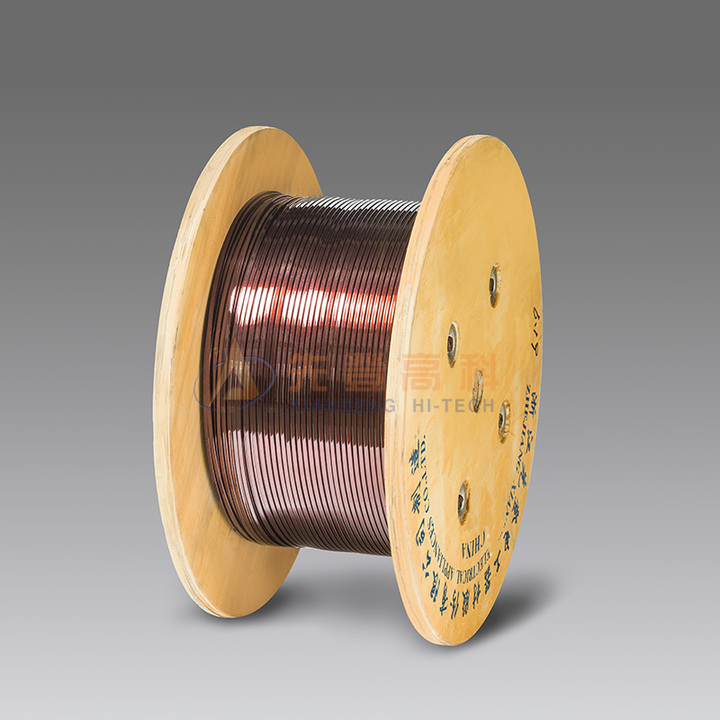

Comparison Of Rectangular Enameled Wire And Copper Wire

-

The rectangular enameled wire is the main type of winding wire, which is composed of a conductor and the insulating layer. After the bare wire is annealed and softened, it is painted and baked several times. However, it is not easy to produce products that meet standards and customer requirements. It is affected by factors such as raw material quality, process parameters, production equipment, and the environment. Therefore, the quality characteristics of various enameled wires are different, and the mechanical properties, chemical properties, electrical properties, and thermal properties are also different.

In life, practical copper wires are used as leads. Good electrical conductivity, widely used in the manufacture of wires, cables, brushes, etc.; good thermal conductivity, usually used to manufacture magnetic instruments, meters, such as compasses, aviation instruments, etc., must be protected against electromagnetic interference; excellent plasticity, It is easy to be processed by hot pressing and cold pressing, and can be made into copper materials, such as tubes, rods, wires, strips, strips, plates, and foils. There are two types of pure copper products: smelted products and processed products. Due to the relatively high cost of copper, sometimes people also use CCA wire instead of pure copper to know about wires and cables, etc.

-