Categories

Tags

-

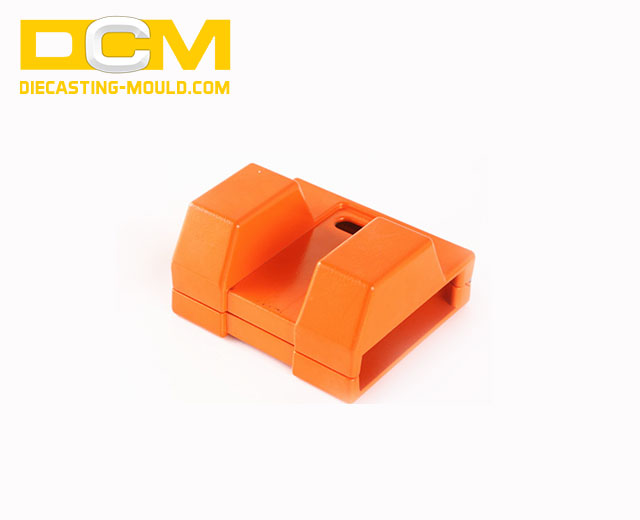

#zinc die casting products

#ISO9000 Quality System Audit

#carpet tiles

#NBA 2K23

#Diablo

#Factory Audit Service

#Centrifuges

#die casting manufacturer

#carbon fiber cutting service

#laboratory refrigerator

#Intelligent Vertical Carousel Manufacturer

#Plastic Machining Services

#loose wave wigs

#raised access floor

#most lifelike sex dolls

#die casting mould

#cmm inspection services

#machining

#Titanium CNC Machining Services

#custom cosmetics

#aluminum alloy die casting

#eva adhesive film

Archives

These surface treatments can include the following types of tre

-

What accounts for the fact that some of the prices are significantly lower while others are significantly higher?Why is there such a significant difference in price between the two options?Because its natural quality and service life are superior to those of fake or low-quality steel, the use of imported mold steel must be more expensive than the use of fake or low-quality steel. This is because its natural quality is superior to those of fake or low-quality steel. This is due to the fact that its natural quality is superior to those of steel that is either fake or of low quality. Either a 3D drawing paper or a test product of the product that needs to have aluminum alloy die casting its openings opened is required in order to calculate the cost of the metal die-casting mold. There are some shady stores that like to put in a lot of effort on mold shells, and in order to make mold shells at a low cost, they use poor-quality mold steel and cut corners wherever they can. In order to avoid being caught, customers should avoid purchasing mold shells from these stores. Customers who shop at these establishments should steer clear of purchasing mold shells if they want to avoid getting caught. Customers who frequent these businesses should abstain from purchasing mold shells if they do not want to run the risk of being caught. Inherent quality and service life of imported mold steel are superior to that of counterfeit or low-quality mold steel, respectively. Imported mold steel also has a higher overall quality. Additionally, the lifespan of imported mold steel is significantly longer.

Die-casting mold shells typically come with a hefty price tag attached to them. This is due to the fact that the raw materials that are used in their production are of an exceptionally high quality, and therefore must be imported. Because of this, the raw materials have to be brought in from elsewhere. It is of the utmost importance to make a distinction between these two things. Even though there is a growing number of aluminum alloy die-casting plants, each of which is able to guarantee standardized management, there is only a very small number of aluminum alloy die-casting plants that have an effective management system, and the majority of these plants are located in China. In spite of the fact that there is a growing number of aluminum alloy die-casting plants, each of which is able to guarantee standardized management, there is aluminum die casting only a very small number of aluminum alloy die-casting plants thatMold shells used for die-casting almost always have a core made of sand embedded inside of them. Sand cores are typically included at no additional cost when purchasing die-casting mold shells. Mold shells used in die-casting typically include the following components:.

Surface treatments of various kinds are almost always aluminum die castings applied to die castings made of zinc alloys. These surface treatments can include the following types of treatments:.

Die-casting of zinc alloys is being carried out by an ever-increasing number of manufacturers in Dongguan, and as a result, the quality of the finished products is quickly improving in order to keep up with the demand. Even though the earlier color development trend of a single product has morphed into the trend of a product that features a variety of colors, many customers are interested in the zinc alloy die-casting factory in Dongguan. This is despite the fact that the trend of a product that features a variety of colors has become more popular. Despite the fact that there is a wide range of color options available for the product in question, this is still the case. Xiangyu, a worker at the Dongguan Zinc Alloy Die Casting Factory, will provide an overview of the topic in the paragraphs that follow. Xiangyu's perspective can be found in the following paragraphs.

What accounts for the fact that some of the prices are significantly lower while others are significantly higher?Why is there such a significant difference in price between the two options?Because its natural quality and service life are superior to those of fake or low-quality steel, the use of imported mold steel must be more expensive than the use of fake or low-quality steel. This is because its natural quality is superior to those of fake or low-quality steel. This is due to the fact that its natural quality is superior to those of steel that is either fake or of low quality. Either a 3D drawing paper or a test product of the product that needs to have its openings opened is required in order to calculate the cost of the metal die-casting mold. There are some shady stores that like to put in a lot of effort on mold shells, and in aluminum casting factory order to make mold shells at a low cost, they use poor-quality mold steel and cut corners wherever they can. In order to avoid being caught, customers should avoid purchasing mold shells from these stores. Customers who shop at these establishments should steer clear of purchasing mold shells if they want to avoid getting caught. Customers who frequent these businesses should abstain from purchasing mold shells if they do not want to run the risk of being caught. Inherent quality and service life of imported mold steel are superior to that of counterfeit or low-quality mold steel, respectively. Imported mold steel also has a higher overall quality. Additionally, the lifespan of imported mold steel is significantly longer.

Die-casting mold shells typically come with a hefty price tag attached to them. This is due to the fact that the raw materials that are used in their production are of an exceptionally high quality, and therefore must be imported. Because of this, the raw materials have to be brought in from elsewhere. It is of the utmost importance to make a distinction between these two things. Even though there is a growing number of aluminum alloy die-casting plants, each of which is able to guarantee standardized management, there is only a very small number of aluminum alloy die-casting plants that have an effective management system, and the majority of these plants are located in China. In spite of the fact that there is a growing number of aluminum alloy die-casting plants, each of which is able to guarantee standardized management, there is only a very small number of aluminum alloy die-casting plants thatMold shells used for die-casting almost always have a core made of sand embedded inside of them. Sand cores are typically included at no additional cost when purchasing die-casting mold shells. Mold shells used in die-casting typically include the following components:.

Surface treatments of various kinds are almost always applied to die castings made of zinc alloys. These surface treatments can include the following types of treatments:.

Die-casting of zinc alloys is being carried out by an ever-increasing number of manufacturers in Dongguan, and as a result, the quality of the finished products is quickly improving in order to keep up with the demand. Even though the earlier color development trend of a single product has morphed into the trend of a product that features a variety of colors, many customers are interested in the zinc alloy die-casting factory in Dongguan. This is despite the fact that the trend of a product that features a variety of colors has become more popular. Despite the fact that there is a wide range of color options available for the product in question, this is still the case. Xiangyu, a worker at the Dongguan Zinc Alloy Die Casting Factory, will provide an overview of the topic in the paragraphs that follow. Xiangyu's perspective can be found in the following paragraphs.

When the surface of the zinc alloy die castings are treated, the castings take on an appearance that is more complex, and as a result, there is a high level of demand from customers for the castings. Die castings made from zinc alloys can have a straightforward appearance if the surface of the castings has not been treated in any way. In today's society, having a conversation about the quality of products is becoming an increasingly important topic of conversation. When looking for zinc alloy die casting manufacturers to work with, many people will give careful consideration to the quality of the zinc alloy die castings they purchase. Because of the significance of the zinc alloy die castings, this is the result. This is an obvious conclusion drawn from the point that was made before this one.

When looking for a zinc alloy die-casting manufacturer in Dongguan, it is therefore absolutely necessary to keep certain criteria in mind. Take into consideration the requirements die casting mould that pertain specifically to you. If an organization's service is not operational, resolving any issues that may arise in the future will be very difficult, demanding a significant amount of effort, time, and possibly even financial resources; as a result, it will not be worthwhile. If an organization's service is not operational, it will be very difficult to resolve any issues that may arise in the future. If a company or organization does not have a service that is functional, it will be difficult to solve any problems that may occur in the future.

The electrophoretic paint process results in the production of a film that outperforms other painting methods in terms of its strength, adhesion, resistance to corrosion, performance under impact, and performance under penetration. The electrophoretic paint process also produces a film that is thinner than other painting methods. The process of electrophoretic painting results in a film that is significantly thinner than films produced by other painting methods. Sand is used as the medium, which is ultimately what makes it possible to accomplish this objective. This is what makes it possible to do so. This not only improves the adhesion between it and the coating, but it also increases the die casting manufacturer performance of the coating film, which is beneficial to the smooth and smooth decoration of the coating. Specifically,In particular, this is as a result of the fact that the application process for electrophoretic paint involves the use of an electrostatic charge. In addition to that, there is the possibility that it could be used as a treatment against corrosion. This would be a very useful application.

Sand is used as the medium, which is ultimately what makes it possible to accomplish this objective. This is what makes it possible to do so. This not only makes the adhesion between it and better, but it also makes the adhesion between it and better. In most cases, zinc alloy die castings are used on the product's exterior in order to carry out surface treatment and prevent corrosion. This is because corrosion is the root cause of a decline in product quality. The parameters of the treatment are determined not only by the characteristics of the product but also by the result that is desired from the natural surface treatment. Sandblasting is only one of many different methods that aluminum die casting parts can be used to treat the surface of an object. There are a variety of other choices accessible to you. The process of printing on stencil packaging incorporates a variety of printing methods, including transcription, perforation, spray printing, and screen printing, amongst others. The deterioration in the quality of the product as a whole can be attributed to corrosion.