Categories

Tags

Archives

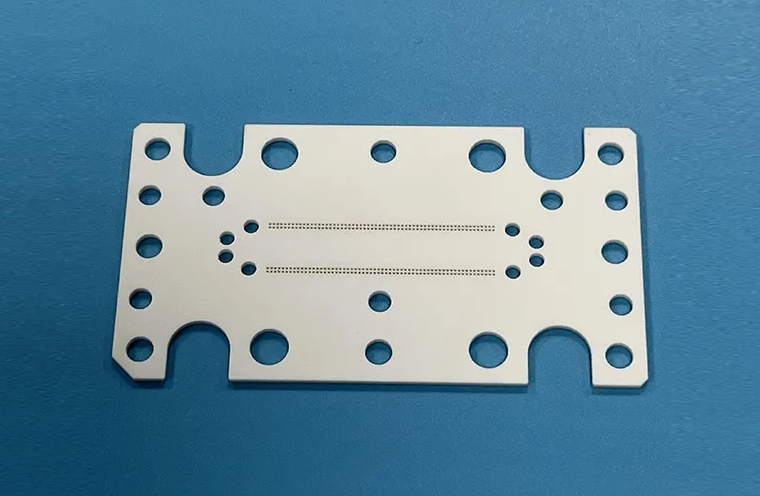

Precision Excellence: Crafting High-Quality Zirconia Ceramic Pa

-

Posted by TTTTT KKKKK - Filed in Arts & Culture - 237 views

In the realm of advanced manufacturing, precision is paramount, and when it comes to ceramic components, the expertise of crafting intricate parts is truly an art. This is precisely where our specialization lies — we are dedicated to the production of high-quality ceramic parts, specifically zirconia, catering to various equipment needs. In this article, we will delve into the nuances of our craftsmanship, highlighting our key strengths and the processes that set us apart.

Specialization in Zirconia Ceramic Parts

Our forte lies in the production of ceramic parts, with a special focus on zirconia. Zirconia, known for its exceptional hardness, wear resistance, and thermal stability, is a material that finds applications in a myriad of industries. From medical devices to industrial machinery, our ceramic parts serve a diverse range of purposes. The choice of zirconia is strategic, as it ensures durability and reliability in the face of demanding conditions.

Extensive Experience with Shaped Ceramic Parts

Crafting ceramic parts requires not only technical prowess but also a deep understanding of various shapes and forms. Our team boasts extensive experience in working with all types of shaped ceramic parts. Whether it’s intricate geometries or unique designs specified in drawings, we have the expertise to transform these ideas into tangible, high-precision components. This versatility sets us apart in the competitive landscape, as we can cater to the unique needs of different industries.

Tailored Production Process for Optimal Results

Each project we undertake is unique, and we understand the importance of tailoring our production process accordingly. Based on the number of ceramic parts outlined in the drawings and the specific shapes required, we meticulously choose a production process that ensures a perfect balance between high quality, short cycle time, and cost-effectiveness. This bespoke approach allows us to deliver not just products, but solutions that align seamlessly with the expectations of our clients.

Ensuring High Quality

Quality is non-negotiable in our commitment to excellence. Our production processes are designed to adhere to stringent quality control measures at every stage. From raw material selection to the final inspection of finished products, we maintain a rigorous quality assurance protocol. This dedication to quality ensures that each ceramic part leaving our facilities meets the highest standards, providing our clients with components they can trust.

Short Cycle Time for Timely Deliveries

In the fast-paced world of manufacturing, timelines are critical. Recognizing this, we have optimized our processes to ensure short cycle times without compromising on quality. This efficiency allows us to meet deadlines and deliver products in a timely manner. Whether it’s a small-scale order or a large-scale production run, our commitment to timely deliveries remains unwavering.

Cost-Effectiveness without Compromise

While precision and quality are our hallmarks, we understand the importance of cost-effectiveness. Through strategic process optimization and a keen focus on efficiency, we offer competitive pricing without compromising on the excellence of our products. This commitment to providing value for money positions us as a trusted partner for businesses seeking reliable ceramic solutions.

In conclusion, our dedication to the production of zirconia ceramic parts is a testament to our commitment to precision, quality, and client satisfaction. With a specialized focus, extensive experience, and a tailored production process, we stand as a reliable partner for industries seeking top-notch ceramic components. As we continue to push the boundaries of ceramic craftsmanship, our clients can trust us to deliver excellence with every precision part we create.