According to the company's website in order to establish a manu

-

Posted by Mignon Blume - Filed in Arts & Culture - 751 views

Phoenix Solar Thermal Inc., a CEM company dedicated to the development of the solar thermal industry in North America, including Canada, has agreed to establish a production line for the T160 Solar collector as part of a framework agreement with Absolicon.These principles are as follows:Furthermore, it outlines the procedures that must be followed prior to the signing of a legally binding agreement for the acquisition of a powder coating spraying production line.

Phoenix Solar Thermal, a regional leader in the development and design of custom engineered energy systems, brings qualified experience in thermal energy to the partnership, which is complemented by CEM Group's qualified experience in thermal energy gained over the course of its many years in the industry.

It is the first step in the process to transfer ownership of the manufacturing line.

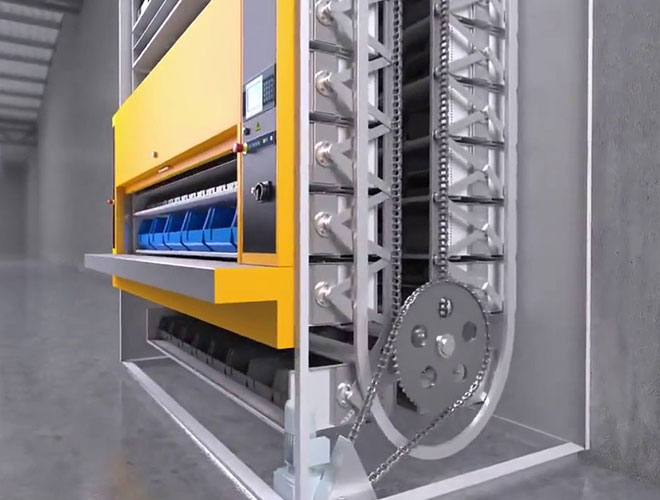

This line is being operated by Absolicon, a Swedish company that has previously delivered a similar Production Line to the Chinese province of Sichuan. Absolicon is currently running a line that is very similar to this one in operation. It is possible to produce solar collectors on the line at a rate of 50 MW (eight thousand thousand collectors) per year. The line is equipped with two six-axis robots, which can produce a total of eight thousand thousand collectors per year. Additionally, in addition to the hardware it sells, Absolicon offers marketing and technical support consulting services, as well as software development and technical training.

According to current estimates, the total estimated value of the hardware and activities covered by the agreement is approximately €4-5 million, resulting in a significant cost savings for the organization.

It is the third item on this list that is concerned with the provision of raw materials.

Absolicon gains access to patented components and high-quality inputs that are partially manufactured in Canada or locally powder coating spraying production line at the installation site as a result of the agreement with the manufacturer. Absolicon also gains access to patented components and high-quality inputs that are partially manufactured in Canada or locally at the installation site.

Absolicon estimates that material purchases will total € 10-15 million per year in order to reach full capacity, with 30% - 40% of purchases likely to be made through the company and 60% - 70% of purchases likely to be made through local subcontractors, according to information provided by the company. The performance of Absolicon's ongoing material investment will determine a significant portion of the company's overall performance over the long term, particularly in the short term.