Categories

Tags

-

#Timing Advance Processor

#LPG Injection Kit

#LPG Emulator

#CNG Pipe

#ECU

#LPG regulator

#CNG LPG ECU

#CNG Emulator

#LPG CNG Switch

#CNG Injection Kits

#Timing Advance Processor CNG Pipe

#LPG Emulator CNG Pressure Gauge

#LPG Emulator CNG Pressure Gauge

#CNG LPG ECU CNG Regulator

#CNG LPG ECU CNG Regulator

#Lpg Cng Switch Supplier

#Lpg Cng Switch Factory

#Cng Conversion Kits

#Cng Conversion Kits Factory

#Cng Lpg Ecu Supplier

#CNG Emulator Suppliers

Archives

Understand The Working Principle Of CNG LPG ECU

-

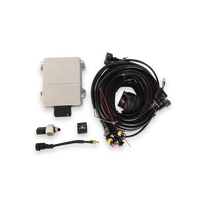

Many people don't know much about CNG LPG ECU . Today we will talk about its workflow.

First, signal processing is performed through the input loop. If it is a digital signal, it directly enters the CPU via the buffer and I/O interface circuit according to the arrangement of the CPU. If it is an analog signal, it will first be converted into a digital signal by an analog/digital (A/D) converter for processing by the digital single-chip microcomputer, and then it can be input to the CPU through the I/O interface circuit. Most information is temporarily stored in RAM and then transferred from RAM to CPU according to control instructions.

The next step is to introduce the best test data pre-stored in the ROM into the CPU, and compare the information input by the sensor with it. The CPU sequentially samples various information from the sensor, performs logical operations with the best test data, makes a judgment result through comparison and sends out instruction signals, and controls the action of the actuator through the I/O interface circuit and output loop. If it is a fuel injector drive signal, it controls the start time and duration of fuel injection to complete the fuel injection control function; if it is an igniter drive signal, it controls the ignition conduction angle and ignition timing to complete the control ignition function. If the actuator needs to be driven by a linear current, the microcontroller controls the duty cycle to control the on and off of the output loop, so that the average current flowing through the solenoid coil of the actuator linearly increases or decreases.

For more details, please visit CNG Regulator .