It is the purpose of this page to provide you with additional i

-

Posted by Moorsel Bas - Filed in Arts & Culture - 574 views

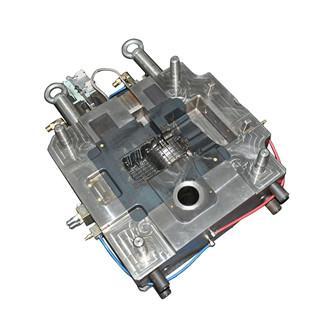

Temperature control is critical in the production of aluminum alloy die-castings, as previously stated. It is also one of the most important components of the process, as previously discussed in greater depth. The costs of casting manufacturing and the economic benefits that can be realized as a result of casting manufacturing are inversely proportional to one another in this context. Create a temperature field in the mold that is within process parameters in order to achieve acceptable external and internal quality on both the outside and the inside of the castings in order to produce castings with acceptable external and internal quality on both the outside and internal surfaces of the castings. A collection and distribution box has been decided to be integrated into the system in order to ensure that the pressure is maintained at a sufficient level at any time.

In order to prevent cast iron cracking during the hot section of a casting's life, die casting aluminum is necessary to employ high-pressure point cooling in the casting's core during the hot section of the casting's life during the hot section of the casting's life during the hot section of the casting's life during the hot section of the casting's life during the hot section of the casting's life during the hot section of the casting's life during the hot section of the casting's life during the hot section of the casting.

Historically, traditional water treatment methods in manufacturing have not been able to meet water quality requirements. This has resulted in clogged cooling pipes near their points of use, as well as other unfavorable downstream consequences. In this situation, the application of a softening agent is a common treatment option, and it is considered standard practice in the industry as a result. In spite of the fact that contaminant-to-pure-water conversion through the use of reverse osmosis (RO) devices causes significant losses in terms of human resources, material resources, and financial resources, the widespread use of water-treatment devices such as reverse osmosis (RO) causes significant losses in terms of human resources, material resources, and financial resources.

While the conversion of contaminated die casting manufacturer water to pure water through the use of these devices results in significant losses in terms of human and material resource consumption, along with a corresponding loss in terms of financial resource consumption, these devices are still in widespread use today. It is possible to reach absolute zero temperature as soon as you have reached the thermodynamic equilibrium state.