It is impossible to anodize cast iron castings because of the n

-

Posted by Moorsel Bas - Filed in Arts & Culture - 710 views

It is important to note that because die cast aluminum adc6 is made from an aluminum magnesium alloy, it will be much easier to anodize and the appearance effect of surface treatment will be much better than that of ADC12 because its silicon content is typically less than 1.0%. Die cast aluminum adc6 will be much easier to anodize and the appearance effect of surface treatment will be much better than that of ADC12. When compared to die cast aluminum ADC12, die cast aluminum ADC6 will be much easier to anodize and the appearance effect of surface treatment will be much better. ADC6 will be much easier to anodize than die cast aluminum ADC12, and the appearance effect of surface treatment will be much better when compared to cnc machining services cast aluminum ADC12. When compared to die cast aluminum ADC12, ADC6 will be significantly easier to anodize, and the appearance effect of surface treatment will be significantly better when compared to die cast aluminum ADC12.

Anodizing and surface treatment on ADC6 will be significantly easier than on die cast aluminum ADC12. The visual effect of surface treatment will be significantly better than on die cast aluminum ADC12 when compared to die cast aluminum ADC12. Anodizing and surface treatment on ADC6 will be significantly less difficult than on ADC12, which is made of die cast aluminum. When comparing die cast aluminum ADC12 to die cast aluminum ADC12, the visual effect of surface treatment will be significantly better on the die cast aluminum ADC12. Anodizing and surface treatment on ADC6 will be significantly less difficult than on ADC12, which is made of die cast aluminum and will require significantly more effort. When comparing die cast aluminum ADC12 to die cast aluminum ADC12, the die cast aluminum ADC12 will have a significantly better visual effect due to the surface treatment than the die cast aluminum ADC12. Because ADC6 is made of die cast aluminum, anodizing and surface treatment will be significantly easier on it than it will be on ADC12, which is made of aluminum and will require significantly more effort. precision die casting supplier cast aluminum ADC12 will have a significantly better visual effect than die casting services cast aluminum ADC12 when compared to die cast aluminum ADC12. This is due to the surface treatment applied to the die cast aluminum ADC12. The fact that ADC6 is made of die cast aluminum means that the process of anodizing and surface treatment will be significantly less difficult than it will be on ADC12, which is also made of aluminum and will require significantly more effort. When comparing die cast aluminum ADC12 to die cast aluminum ADC12, die cast aluminum ADC12 will have a significantly better visual effect than die cast aluminum ADC12. This is due to the surface treatment applied to the die cast aluminum ADC12 during the manufacturing process. It is possible to improve the anode layer's wear resistance, corrosion resistance, and weather resistance, to name a few of the properties that can be improved with proper maintenance of the anode layer. There are numerous other properties that can be improved with proper maintenance of the anode layer. By increasing the hardness and corrosion resistance of the anode layer, the addition of a hard coating to the anode layer can improve the reliability and quality of the anode layer, as well as its overall performance. As a result of the reduction in corrosion, hard anodizing treatment can not only reduce the amount of corrosion that occurs, but it can also improve the reliability and quality of the anode layer as a result of the reduction in corrosion. It is also possible to achieve improved corrosion resistance, wear resistance, and weather resistance, to name a few of the characteristics that can be achieved in this manner, by using this method. Anodic pretreatment of water before it is used as a feedstock in the treatment process ensures that the ash is removed from the water prior to the treatment process. In this procedure, aqueous hydrofluoric acid is used, which is diluted in water to achieve the desired acidity before being used. It is possible to use anodic oxidation tanks, which contain the active ingredient sulfuric acid monoacid, to accelerate the oxidation process by acting as an accelerator, resulting in greater efficiency. It is the active ingredient, sulfuric acid monoacid, that is responsible for the electric current generated in the anodic oxidation tank. This experiment will be conducted at low temperatures and high pressures, with a film thickness of at least 100um serving as the absolute bare minimum, after careful consideration of all of the variables. The liquid contained within the anodic oxidation tank requires frequent dosing maintenance and bath reconstruction in order for the system to operate properly.

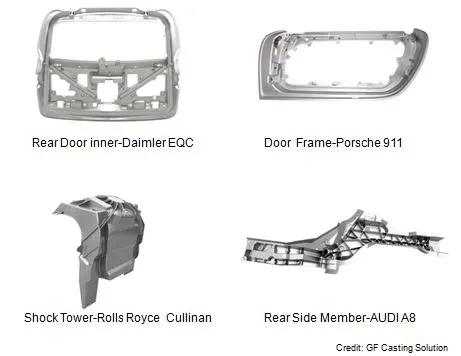

There are numerous colors available for anodizing die cast aluminum, and the metal can be used to protect against corrosion in a variety of applications, including those in the automotive and aerospace industries. Die casting parts can complete the structure, edges and corners, and oxidation quality that forging parts and turning parts / CNC parts are unable to achieve. Die casting parts are also less expensive than forging parts and turning parts. Moreover, China die casting mold casting parts are less expensive than forging and turning components. Furthermore, die casting components are less expensive than components made by forging or turning. Die cast parts are also less expensive than parts made by forging or turning. China die casting manufacturer cast parts are also less expensive than parts that have been forged or turned in the traditional way. Die cast parts are also less expensive than parts that have been forged or turned in the traditional manner of manufacturing. As an added bonus, die cast parts are less expensive than parts that have been forged or turned in the traditional way of manufacturing. As an added benefit, die cast parts are less expensive than parts that have been forged or turned in the traditional way of producing them. Parts that have been forged or turned in the traditional manner are less expensive than parts that have been die cast. Traditionally forged or turned parts are less expensive than die cast parts because they are made in a more traditional manner. At all stages of the process, a strong emphasis on the quality of die castings produced by the process must be placed on the die castings themselves, and this emphasis must be maintained throughout the entire process. Instead of other factors, the ability of a process to control minor adjustments and small details is what determines the overall quality of an anode when it comes to overall performance and performance characteristics, as opposed to other factors. The ability of a process to control minor adjustments and small details are critical in determining how well an anode performs overall. In order to determine how well an anode performs overall, it is necessary to examine how well it performs overall and how well it performs specific performance characteristics.

In the following sections, you will find a detailed illustration of an electric heating die casting die, which can be used to achieve pinpoint accuracy while performing this task.

For this reason, and because equipment for controlling the temperature of aluminum alloy die casting dies has only recently been introduced in the field of environmental protection (as recently as 2005), this category of temperature control equipment is considered to be a new one in the field of environmental protection. A completely new type of temperature control equipment is currently being developed and introduced into the market with the goal of preserving the environment. The fact that this product is intended for use in all aspects of the die casting industry does not preclude it from having a wide range of applications that are not limited to the die casting industry. Diesel can be used to generate electricity in any industry that employs the die casting process, such as the automotive industry, because it is a clean fuel. Mold temperature is maintained stable throughout the manufacturing process through the use of a heat transfer oil (water) circulation pump and heater in conjunction with a control system, pipes, and support frame. When operating a special China die casting manufacturer mold temperature machine with a cooling demand, a sufficient cooling system must be installed in order for the machine to be safe and dependable while also operating according to the machine's design specifications, among other things.

For high-quality die casting to be produced throughout the entire die-casting process, precise control of die temperatures must be maintained throughout the process. Unless this step is completed, the quality of the casting will not be acceptable. In order to achieve the best possible results from the casting operation, it is necessary to pre-heat the die casting mold before beginning the casting process. As a result, in order to achieve this goal, it will be necessary to use a die-casting die warmer during the casting process. The surface temperatures of dies must be maintained at different temperatures from one another in order to ensure that the dies operate properly. This is necessary due to the fact that the surface temperatures of different zinc alloy die casting-casting alloy materials differ from one another. Various temperatures are maintained at various levels on the surfaces of the dies in order to accomplish this. According to industry standards, aluminum alloys are typically used at temperatures ranging from 170 to 220 degrees Celsius, whereas zinc alloys are typically used at temperatures ranging from 220 to 260 degrees Celsius, respectively.