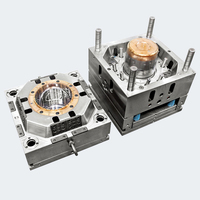

18L Bucket Mould Suppliers Introduces The Knowledge Of Using Pl

-

In the process of use, plastic buckets sometimes become brittle. Fragile plastic buckets will only be damaged, which is not conducive to long-term use. The brittleness of plastic barrels is closely related to the selection of production molds, raw materials, production machinery and production processes. 18L Bucket Mould Suppliers introduced how to avoid embrittlement of plastic buckets.

1. The temperature of the barrel and nozzle is too low and needs to be adjusted. If the material is simply degraded, the temperature of the cylinder and nozzle should be increased.

2. Reduce the back pressure and rotation speed of the screw preform to loosen the material and reduce the deterioration of the plastic due to shearing overheating.

3. The mold temperature is too high and it is difficult to demold. The mold temperature is low, the plastic is cooled prematurely, the fusion joint is poorly fused, and it is easy to crack. It is especially suitable for high melting point plastics such as polycarbonate.

4. The plastic barrel core should have an appropriate demoulding angle. When the core is difficult to demold, the temperature of the cavity should be increased and the cooling time should be shortened. When the cavity is difficult to separate, the temperature of the cavity should be lowered and the cooling time should be prolonged.

Through the above introduction, Paint Pail Mould Suppliers hopes that you can simply refer to the content of this article in future use.