20L Bucket Mould Suppliers Introduces Injection Molding Precisi

-

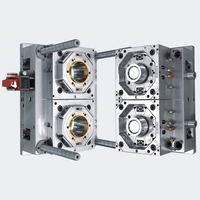

Injection molding precision processing is an industry with a wide range of knowledge, technology and practice. Plastic raw materials, toners, nozzle materials, molds, injection molding machines, peripheral equipment, fixtures, sprays, various auxiliary materials and packaging materials are used in the production process of injection molding precision processing, which brings a lot to the management of the injection molding workshop. Compared with other industries or departments, the requirements for management personnel at all levels of the injection molding workshop are higher. So, how does 20L Bucket Mould Suppliers introduce how injection molding precision processing production works?

Precision injection molding production requires 24-hour continuous operation, usually in two shifts. The injection molding workshop has many jobs, complicated division of responsibilities, and different skills requirements for personnel in different positions. In order to make the production and operation of the injection molding workshop smooth, it is necessary to manage the personnel, materials, equipment, tools, etc. involved in each link and each position, including: raw material room, scrap room, batching room, production site, post-processing Operation and coordination management of areas, tool rooms, semi-finished products areas, offices, etc.

Through the above introduction, 18L Bucket Mould Suppliers hopes that you can simply refer to the content of this article in future use.